News Categories

How Does 36v 250w Electric Bicycle Motor Work?

This part of the role is to convert electrical energy into mechanical motion to drive the wheels forward. The commonly used 36V 250W electric bicycle motor is a permanent magnet DC motor. In order to achieve the operating torque of more than 10 N.m, the power of the motor should be in the range of 100-250W, and the working voltage should be 24 V or 36 v. the motor requires large starting torque, high efficiency, lightweight and certain overload capacity. In addition to the common inner rotor motor with motor wheel through chain drive or direct friction, the outer rotor DC motor can be installed in the middle of the wheel and drive the wheel hub directly through the planetary gear reduction mechanism. This kind of 36V 250W electric bicycle motor is also called hub type motor. It has the advantages of a short transmission chain, high efficiency, and a compact structure. In addition to a permanent magnetic field, series excitation can also be used for DC motor excitation. The series excited DC motor has soft working characteristics, good speed regulation performance, and large starting torque. Although it consumes a little more electricity than the permanent magnet motor, it still has some applications. The price of this kind of motor is very cheap, and it is very cost-effective for users to refit and manufacture. This kind of driving mode is generally acknowledged to be better. It is controversial whether to use a brush motor or a brushless motor.

The output speed of the 36V 250W electric bicycle motor is more than 3000 rpm. The electric hub assembly is composed of a reducer, overrunning clutch, and shell. Its speed is 170-180 rpm, which is suitable for bicycle running at about 20km / h. The structure is of high reliability, low cost, and comfortable riding, but it also has the following disadvantages: (1) traditional brush and commutator have mechanical wear and noise, sparks, and so on. (2) the advanced nature and the grade of the system are not high enough.

The 36V 250W electric bicycle motor is actually composed of two parts. One is the direct external rotor brushless motor system, the other is the special control system that can realize electronic commutation. The brushless motor is gradually mature based on the development of modern IC technology and power electronic devices. It is not difficult for producers with electronic technology experience to master.

A Brushless DC motor is composed of the motor body, position sensor, and an electronic reversing switch circuit. The stator of the position sensor and the electronic reversing switch circuit is equivalent to a static commutator, and the rotor of the position sensor is equivalent to a rotating brush. They constitute an electronic reversing device without mechanical contact.

The motor body consists of several pairs of permanent magnet steel rotors and a multiphase armature winding stator. The armature windings are respectively connected with the corresponding electronic reversing switch circuit. In order to keep the relative relationship between the armature winding current and the magnetic field polarity unchanged, a sensor is set to detect the rotor position, so that the armature winding can be energized in turn with the change of rotor position.

The position sensor is a device for detecting rotor position without mechanical contact. The sensor consists of a stator and a rotor. It is installed in the stator housing and on the main rotor shaft respectively. It can provide signals and trigger the electronic reversing switch circuit in a certain order.

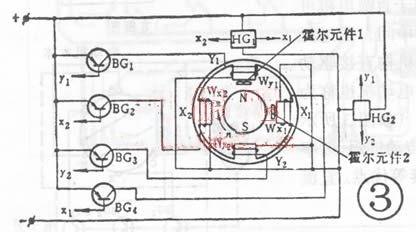

The commonly used position sensor is a magnetic conversion type. The stator of the sensor is the hall element, which is configured in a certain order, and the rotor of the sensor is a permanent magnet.

In the electronic commutation switch circuit, each power element is connected with the corresponding stator winding in series. The conduction and cut-off of each functional element depend on the signal of the position sensor. The conduction of the winding circuit can be one phase to one phase in turn or two phases to two phases in turn.

Hall position sensor has been widely used because of its simple structure, convenient installation, flexibility, and easy mechatronics. The characteristic of the Hall element is: when there is currently flowing through the magnetic field, its transverse potential voltage appears

The control poles of Hall elements are connected to the power supply respectively, and the output terminals x1, X2, Y1, and Y2 respectively output signals to control the on and off of transistors bg1-bg4.

According to the characteristics of the Hall element, when the N pole of the main rotor is at the position of stator Y1, electric potential in the direction of X1 will be generated in the hall element Hg1. This signal will make BG4 turn on, and there will be current flowing through the WX1 winding in series with BG4. The stator X1 pole will be magnetized to the S pole, and the rotor will be attracted to rotate 90 degrees. When the N pole reaches the position of stator x1, the output of Hg1 will be 0, A potential in the direction of Y2 is generated in the hall element Hg2. This signal makes BG3 turn on, makes the winding wy2 have a current flow, and makes the stator Y2 pole magnetized to the S pole, which attracts the rotor to continue to rotate 90 degrees, and the N pole reaches the position of stator Y2. At this time, the output of Hg2 is 0, and the S-pole pair

Accurate. Therefore, the potential in the direction of X2 is generated in Hg1, which also makes BG2 and wx2 on, and makes the rotor continue to rotate for 90 degrees. Therefore, for different positions of the main rotor, the hall element outputs different signals in turn, so that the main stator winding turns on in turn according to the sequence of wx1-wy2 -- wx2-wy1, forming a rotating magnetic field and making the rotor rotate.

In addition to the above 36V 250W electric bicycle motor, there is also a light, small and simple electric auxiliary rod, which can be directly installed on the front fork. It is a good scheme for users to refit electric vehicles.